Boiler systems are complex. It’s easy to overlook certain parts, particularly those that aren’t immediately visible or apparent. One such part is the Boiler Flue.

What is a Boiler Flue?

It functions as the Boiler’s chimney, serving as an escape route for excess heat and by-products generated during the Boiler’s operation.

The Boiler Flue safely transports the waste gases your Boiler produces out of your home. These waste gases consist of water vapour, carbon dioxide, and small traces of other substances.

The Boiler Flue ensures that these gases are expelled into the atmosphere, away from the interior of your house, keeping everyone inside safe.

What Comes Out of a Boiler Flue?

Boilers burn fuel to heat water. This process creates a series of by-products. Predominantly, water vapour and carbon dioxide are released, but there are also trace amounts of other substances.

The most dangerous is carbon monoxide, a colourless, odourless gas that can be lethal if inhaled.

Another potential by-product is nitrous oxide, which, though less lethal, can cause respiratory problems.

The Boiler Flue ensures all these substances are harmlessly vented away from your home.

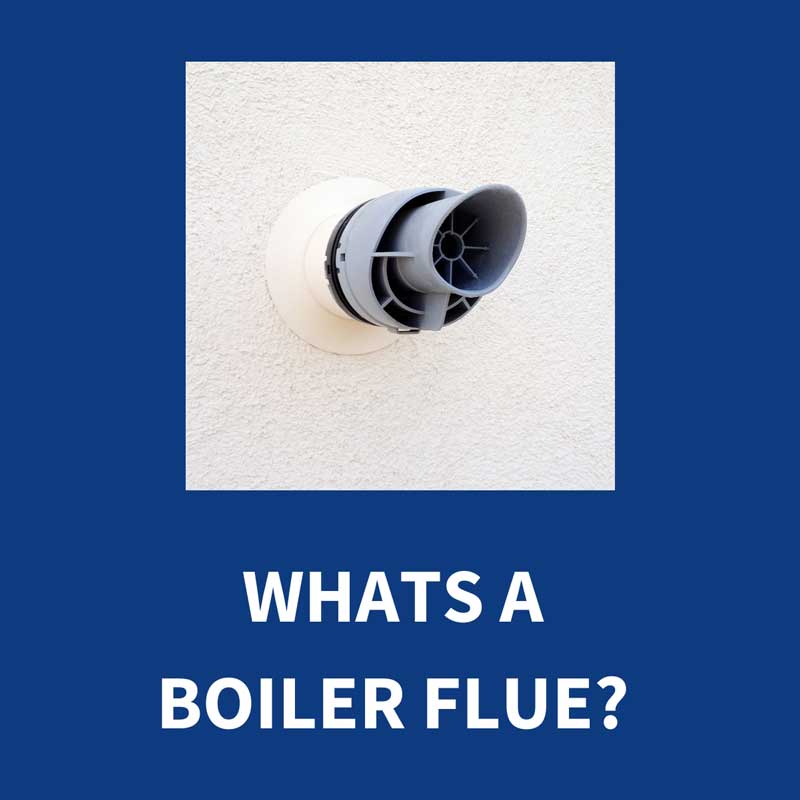

What Does a Boiler Flue Look Like?

Boiler Flues typically come in two shapes: round or square. Round Boiler Flues are more commonly associated with modern boilers, while square flues are often found in older systems.

The exit point of the Flue is visible from the exterior of your home, and on colder days, the expelled fumes are easily seen.

What Happens if a Boiler Flue is Blocked?

A blocked Boiler Flue poses serious health risks as the gases will have nowhere to escape back into your home.

This situation may result in an accumulation of carbon monoxide, leading to carbon monoxide poisoning.

Leaves, insects and other debris can cause blockages. If your boiler flue is blocked, it’s essential to shut off your boiler system immediately and call a Gas Safe Registered engineer to inspect your Boiler and Flue.

What Is a Balanced Flue, a Fanned Flue and an Open Flue?

There are three different types of Flue.

Balanced Flue

A Balanced Flue, as the name suggests, ‘balances’ the intake of combustion air and the expulsion of exhaust gases.

In a Balanced Flue system, the Flue is typically a double-walled pipe or two separate pipes for two purposes.

The outer pipe draws in air from the outside, providing the Boiler with the oxygen it needs for combustion.

The inner pipe expels the by-products of combustion, including gases like carbon dioxide and water vapour, safely out of the building.

Fanned Flue

A Fanned Flue is another type of ‘Closed Flue’ that uses a fan to force gases out, an effective expulsion method that can make the Boiler more efficient.

A fan means that the flue gases can be pushed a longer distance, allowing for more flexibility in where the Boiler can be fitted within the property.

Open Flue

An open flue is a system found on older types of gas Boilers where there isn’t a fan to aid in expelling exhaust gases.

The flue pipe is connected directly to the Boiler and travels vertically through the building to the roof.

The design of the Flue relies on the principle that hot air naturally rises. As the Boiler burns fuel to heat water, the by-products of combustion, including gases like carbon dioxide, are heated and rise up and out through the flue pipe.

Horizontal Vs Vertical Boiler Flues

Boiler Flue placement is either horizontal or vertical.

Horizontal flues are common in modern systems where the Boiler is mounted on an external wall. The Flue passes through the wall, removing the gases from the atmosphere.

Vertical flues, on the other hand, are often used in Boilers located somewhere other than an external wall. These flues are often directed vertically through the roof.

Can A Boiler Flue Be Extended?

Yes, a boiler flue can be extended under certain circumstances. If you’re carrying out a home extension or your current Flue isn’t sufficiently distanced from a window, vent, or door, you may need to extend your Flue.

This is done to ensure it meets regulations for safety and operational efficiency.

When considering a boiler flue extension, refer to your Boiler manual for the recommended specifications. This will help you understand the allowable length and number of bends your Boiler can accommodate.

Always remember, the Flue should ideally be as short and straight as possible to maximise efficiency.

Once you’ve determined the necessary extension details, hiring a qualified Gas Safe Registered Engineer is crucial to do the installation.

The process involves extending the Flue and potentially adjusting the Boiler settings to ensure it works effectively with the extended Flue.

The incorrect installation or unsuitable extension of a Boiler flue can lead to inefficiency, potential carbon monoxide leakage, or other safety risks. Always get the work done by a registered professional.

Regulations Surrounding Boiler Flues

With the inherent risks associated with improper flue installation, strict regulations apply to the placement and installation of Boiler Flues.

The Flue must maintain certain distances from windows, air bricks, corners, and the ground.

Gas Safe Registered Engineers follow these regulations to ensure the Boiler Flue is positioned correctly and safely.

Checking your Boiler Flue

To maintain your Boiler’s safety and efficiency, regular checks and servicing of your Flue are essential. These checks can help detect any blockages or restrictions impacting Flue’s operation. An annual Boiler Service by a Gas Safe Registered engineer will include checking and testing the Boiler Flue, ensuring your Boiler operates safely and efficiently.

If you live in Essex, TM Hughes & Son Gas Services Ltd can service your Boiler and inspect your Flue. Please Contact Us for a free, no-obligation quote.

Hi, I’m Terry, the founder and owner of TM Hughes & Son Gas Services

Please get in touch to book an appointment or receive a free, no-obligation quote

Call – 01245 830075

Email – info@tmhughesandson.uk

0% Finance

For Boiler Installations & Repair