What Is A Boiler Expansion Vessel?

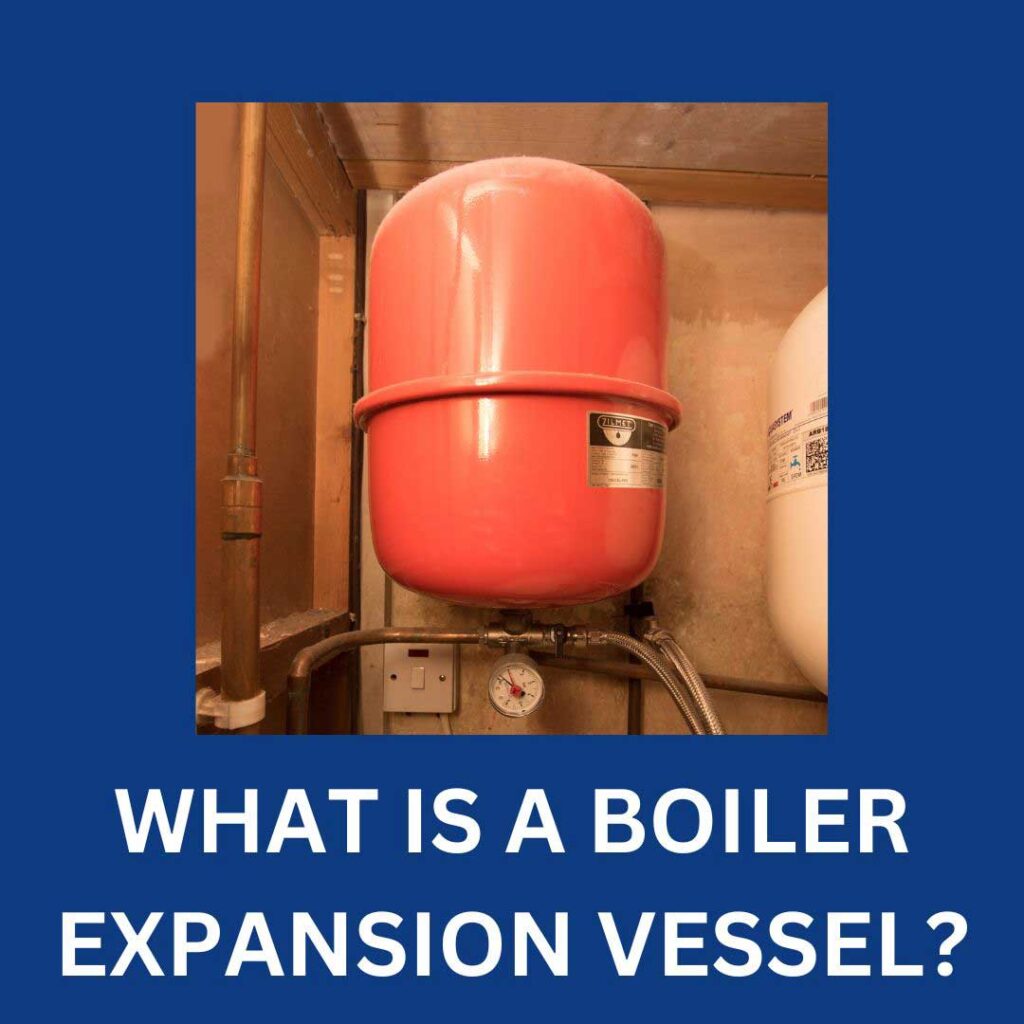

A Boiler expansion vessel is an essential component of pressurised heating systems. The Vessel regulates the expansion of heated water preventing excessive pressure. The Vessel is a sealed metal container divided by a flexible rubber diaphragm, with one side containing air or nitrogen and the other connected to the system’s water.

Introduction To Boiler Expansion Vessels

A Boiler expansion vessel is a small but essential component in many modern central heating systems. It plays an important role in managing the pressure within sealed systems, such as those powered by Combi and System Boilers.

By absorbing the excess pressure caused when water heats and expands, the expansion vessel helps maintain a safe and efficient heating system.

Unlike older open-vented systems that use a feed and expansion tank, sealed systems rely on the expansion vessel to handle pressure changes. This design makes the heating system more compact and less prone to water loss or air entering the system.

Without a functioning expansion vessel, your Boiler could face pressure fluctuations, leading to leaks or damage to key components. Understanding what this Vessel does and why it matters can help you identify potential issues early and keep your heating system running smoothly.

How Does A Boiler Expansion Vessel Work?

A Boiler expansion vessel is designed to manage the natural changes in water pressure when the heating system is in use. As water heats up, it expands, increasing the pressure within the system. Without a way to absorb this pressure, the system could become unsafe or cause damage to components like pipes, valves, or even the Boiler itself.

The expansion vessel is a small tank divided into two chambers by a flexible rubber diaphragm. One side contains water from the heating system, while the other is filled with compressed air or nitrogen. As the water heats and expands, it presses against the diaphragm, compressing the air on the opposite side. This action absorbs the excess pressure, ensuring the system remains stable. This process absorbs the excess pressure, keeping the system stable.

The expansion vessel works with the system’s pressure relief valve, an additional safety feature. If the pressure becomes too high, the valve will release water to prevent damage. However, a properly functioning expansion vessel ensures that pressure levels remain balanced, so the relief valve rarely needs to activate.

By managing pressure effectively, the expansion vessel ensures your Boiler operates safely and efficiently, extending the lifespan of your heating system.

Why Is An Expansion Vessel Important?

Here are the key reasons why an expansion vessel is so important:

Prevents Damage To The System

Excess pressure can significantly strain components such as pipes, joints, and valves. Over time, this could lead to leaks or even system failure. The expansion vessel absorbs the pressure, reducing wear and tear on your system.

Maintains Efficiency

A stable pressure level ensures that the heating system operates as designed. When pressure fluctuates too much, it can affect the Boiler’s performance, causing it to work harder and use more energy. The expansion vessel helps the system run efficiently by regulating the pressure.

Protects The Boiler

Boilers are expensive to repair or replace, so protecting them is vital. The expansion vessel prevents over-pressurisation, which could damage the Boiler’s internal components or lead to a shutdown.

Ensures Safety

High-pressure systems can be dangerous if not properly controlled. The expansion vessel works with other safety features, like the pressure relief valve, to prevent over-pressurisation and keep your home safe.

Signs Of A Faulty Expansion Vessel

Like any working component in your heating system, an expansion vessel can develop problems over time. When it stops working correctly, you might notice issues with your Boiler or central heating system.

Spotting these signs early can help prevent serious damage and costly repairs.

Here are some common signs of a faulty expansion vessel:

Frequent Pressure Drops

If you have to regularly top up the Boiler pressure via the filling loop, the expansion vessel may not be maintaining pressure. A deflated diaphragm or loss of air on the Vessle’s airside is a common cause.

Pressure Gauge Fluctuations

Sudden spikes or drops in the pressure gauge, particularly when the heating is turned on or off, can indicate a problem. A faulty expansion vessel might struggle to absorb the pressure changes effectively.

Water Leaks from the Pressure Relief Valve

The pressure relief valve releases water if the system’s pressure becomes too high. If you notice water dripping from this valve, it could be a sign that the expansion vessel is faulty.

Boiler Lockouts

Many modern Boilers have safety features that shut the system down if the pressure is unstable. Repeated lockouts could point to a failing expansion vessel.

If you notice these signs, contact a gas-safe registered heating engineer ASAP. The engineer can diagnose the issue, re-pressurise the Vessel, or replace it if necessary.

Causes of Expansion Vessel Issues

A faulty expansion vessel can disrupt your heating system, but understanding what causes these problems will help you prevent or address issues quickly.

Here are some common reasons why an expansion vessel might fail:

Loss of Pressure in the Air Chamber

The air or gas inside the expansion vessel is vital for absorbing pressure changes. Over time, this air can escape due to a slow leak, poor sealing, or wear and tear. Without enough air, the Vessel can’t work properly.

Diaphragm Damage

The flexible diaphragm that separates the water and air chambers can weaken or split over time. When this happens, water and air mix, and the Vessel loses its ability to balance the system pressure.

Over-Pressurisation

Excessive system pressure, often caused by overfilling the Boiler, can strain the expansion vessel. Repeated high pressure can damage the diaphragm or cause leaks in the Vessel.

Age & Wear

Like any working part, expansion vessels have a limited lifespan. Older vessels may develop leaks, lose pressure, or suffer general wear..

Incorrect Installation Or Sizing

If the expansion vessel is too small for the heating system or installed incorrectly, it won’t be able to manage pressure effectively. This can lead to early failure or ongoing pressure problems.

Lack Of Maintenance

Expansion vessels require periodic checks to ensure they’re functioning correctly. Neglecting maintenance increases the risk of unnoticed issues developing over time.

To avoid these problems, having your Boiler serviced and heating system checked by a qualified professional at least once a year is important.

Annual checks will help catch early signs of wear or damage, extending the life of your expansion vessel and ensuring the safety and efficiency of your heating system.

How to Address Expansion Vessel Problems

If you suspect an issue with your Boiler’s expansion vessel, it’s important to act quickly to prevent damage or disruption to your heating system.

Here’s a step-by-step guide on what to do:

Check the Pressure Gauge

Start by examining the Boiler’s pressure gauge. A system regularly losing pressure or showing significant fluctuations may point to an expansion vessel issue.

Inspect the Pressure Relief Valve (PRV)

Look for any signs of water dripping from the PRV. Leaks here are often a symptom of an over-pressurised system caused by a faulty expansion vessel.

Call a Qualified Heating Engineer

It’s essential not to attempt DIY repairs on a Boiler expansion vessel. Boilers and central heating systems are complex; improper repairs can cause serious damage and pose safety risks. Always use a Gas Safe registered engineer to diagnose and fix any issues. The engineer will:

Re-Pressure the Expansion Vessel

If the issue is a loss of air pressure in the Vessel’s air chamber, the engineer should be able to re-pressurise it using a hand pump. This is a common fix for minor issues.

Replace the Expansion Vessel if Necessary

If the diaphragm is damaged or the Vessel is beyond repair, a replacement will be required. This involves draining the system and installing a new expansion vessel.

Test the System

After repairs or replacement, the engineer will test the system to ensure pressure levels are stable and the Boiler operates safely.

Need Help With Your Expansion Vessel?

We are a team of experienced Gas Saf registered engineers serving Essex. If you live in the county and require help with your expansion vessel or any other component of your central heating system, please contact us.

Hi, I’m Terry, the founder and owner of TM Hughes & Son Gas Services

Please get in touch to book an appointment or receive a free, no-obligation quote

Call – 01245 830075

Email – info@tmhughesandson.uk

Get A Free Boiler Quote

0% Finance

For Boiler Installations